October 18, 2024

What You Should Know For The Transition To A2L Refrigerants

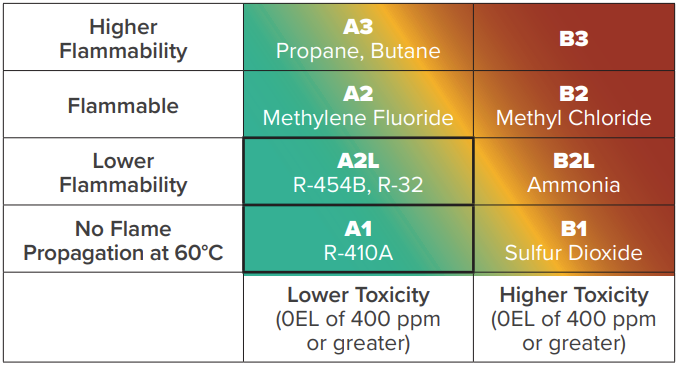

In 2025, the A2L standard for HVAC refrigerants mandates a Global Warming Potential (GWP) of under 700. The

low GWP of A2L refrigerants can increase system efficiency and lower emissions by reducing energy consumption.

While slightly more flammable than A1s like R-410A, A2Ls are significantly safer than A3s such as propane.

A2L Cylinders

You can easily identify A2L cylinders by several

distinctive attributes compared to current models:

- Left-handed threading (requires use of adapters)

- Gray cylinders with a red band on the top

- Equipped with pressure release valves instead of

rupture discs (to enhance safety during handling

and storage)

Sell-Through Categories

- PRODUCT: Packaged units (commercial and

residential), window units, PTACs, etc.: 3-year

sell-through timeline. - SYSTEMS: Split units installed, connected and

charged onsite (residential, commercial and ductless): 1-year sell-through timeline. - COMPONENTS: Split units and parts used for service and repairs (condensers, coils, parts, etc.): no specific sell-through limit.

- Split system inventory will start transitioning beginning in late summer/early fall 2024, and packaged equipment winter 2024 into Q1 of 2025.

R-410A products are not compatible with A2L products and cannot be matched together. A2L equipment will have built-in or field-installed safety features to mitigate refrigerant leak situations. There is no one standard in refrigerants in this transition—R-454B and R-32 will be the main ones used by manufacturers.

Myths Vs. Facts

MYTH: A2Ls are “new” and “untested”.

FACT: A2L refrigerants have been used globally in HVAC systems and in US appliances, automobiles and small HVAC applications for years. Over 90% of new cars and many window units and appliances today use A2L refrigerants.

MYTH: New A2L refrigerants are propane-based.

FACT: A2L refrigerants do NOT contain hydrocarbons or propane.

MYTH: These new refrigerants are highly flammable

and dangerous.

FACT: A2Ls are classified as “mildly flammable” due to

higher flammability limits, higher ignition energy levels

and lower heat of combustion compared to propane

or acetylene. With proper safety protocols, tools and

practices, the transition to A2Ls is not as hazardous

as perceived.

MYTH: I need to buy all new tools.

FACT: While some tools like vacuum pumps, recovery machines and older manifolds may need to be replaced, many A2L-ready products are already in use. Check your inventory for compatibility. Some digital tools might only need a software upgrade, while others might require additional adapters or accessories.

MYTH: We need to redo our EPA exam to handle A2L equipment.

FACT: Current EPA Section 608 certification holders are grandfathered in and do not need to retake the exam. Continuing education on A2L safety and service is encouraged.

A2L Tool Compatibility

| Service Tool | A2L Compatibility |

| Analog Gauge Manifold | Needs to Reflect Saturation Temps (R-32/R-454B/R-410A) |

| Digital Gauge Manifold/Probes | May Need to Update Software to Include A2L Refrigerants |

| Charging Hoses | No Change Needed, but A2L Hoses Available with Left-Handed Thread Adapter Included |

| Torque Wrench | No Change |

| Flaring Tool | No Change |

| Pipe Cutter | No Change |

| Pipe Bender | No Change |

| Hex Wrench | No Change |

| Ventilation Fan (if Low Ventilation) | No Change |

| Scales | No Change |

| Vacuum Pump | Switch Located Away from Work Zone, or A2L Compatible One |

| Fire Extinguisher | Chemical Compatible for A2L Refrigerants (Class B Dry Powder) |

| Gas Detector | Need A2L Compliant |

| Electronic Leak Detector | Need A2L Compliant |

| Refrigerant Recovery Cylinder | Need A2L Compliant (Left-Handed Thread, GHS Label) |

| Recovery Machine | Need A2L Compliant |

| Electric Hand Tools | Non-Sparking Recommended |

Products you need to know for A2L

Reverse thread adapters are needed for refrigerant access to R-32 and R-454B reverse threaded cylinders.